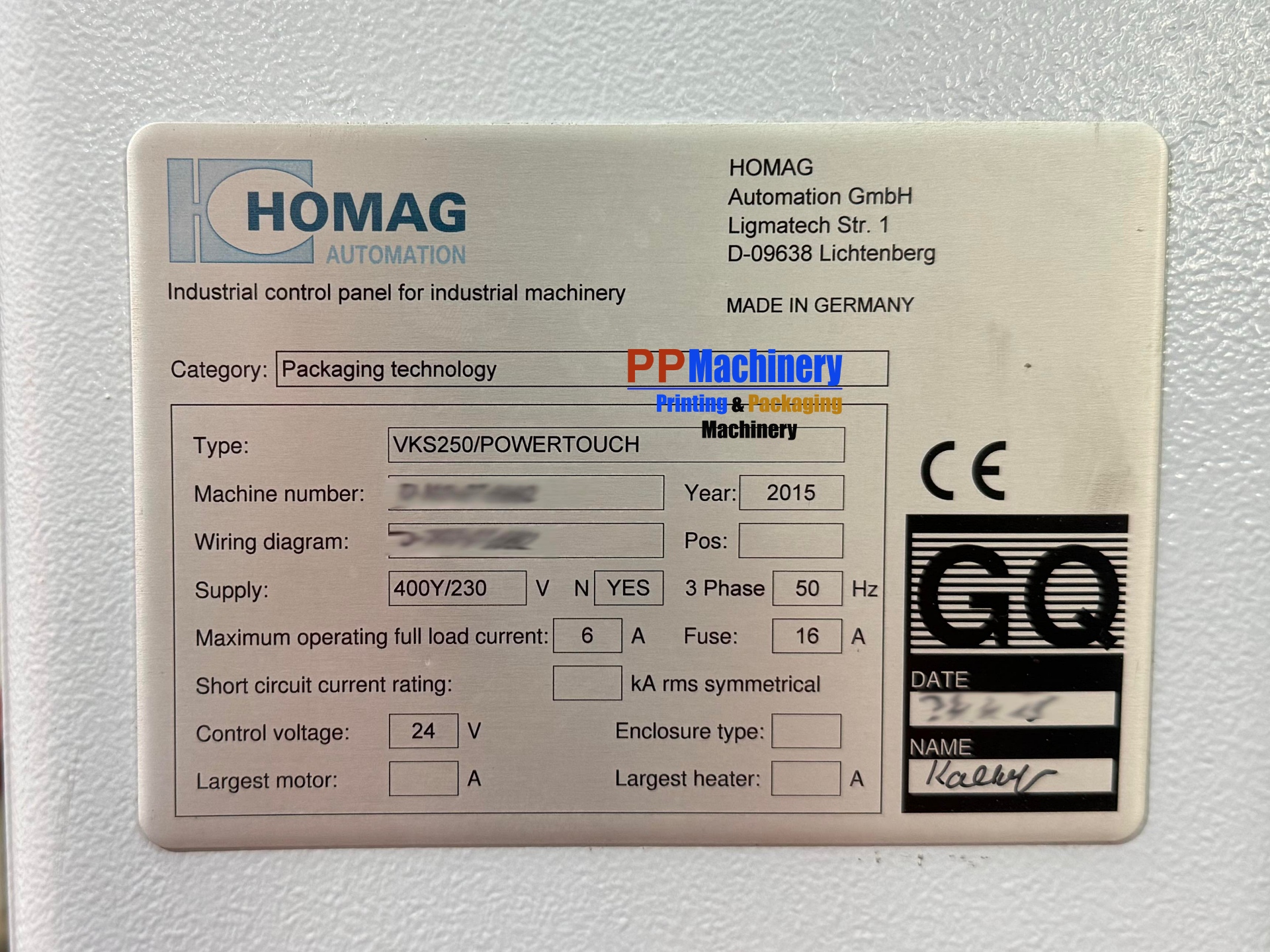

HOMAG AUTOMATION VKS 250 Profiline Powertouch from 2015

Automatic Cardbox cutting machine – Boxmaker

Technical data

Carton thickness : 2,5 to 6,5 mm

Carton quality : in accordance with DIN 55468

• 1-wall; thickness up to around 4 mm (quality 1.10 to 1.40)

• 2-wall; thickness up to around 6,5 mm (quality 2.10 to 2.30)

Web width infeed transport : 350 bis 2.500 mm

Web width „Side by side“ : Summe maximal 2.350 mm

Stacking height : up to 2.150 mm inkl. panel

Division continuous material : 1.150 mm

Description

Automatic Cardbox cutting machine – Boxmaker

Technical data

Carton thickness : 2,5 to 6,5 mm

Carton quality : in accordance with DIN 55468

• 1-wall; thickness up to around 4 mm (quality 1.10 to 1.40)

• 2-wall; thickness up to around 6,5 mm (quality 2.10 to 2.30)

Web width infeed transport : 350 bis 2.500 mm

Web width „Side by side“ : Summe maximal 2.350 mm

Stacking height : up to 2.150 mm inkl. panel

Division continuous material : 1.150 mm

1st Feed of raw carboards

Endless cartons from the stack which are being manually fed once via the coilers of the machine. It can be fed sinle or double coursed depending on how big the carton cuts turn out.

Optional extension allow the expansion upt o 12-coursed, fully-automatic infeed.

• With the single-coursed feed cuts can take place simultaneously

• With the double-coursed feed thick and thin cartons can be processing in alternation, e.g. from one course the cartons are being cut and from the other course bars for the sub-division within the cartons are being cut.

Single carton blades can be fed (optionally) via the single-blade infeed and a lifting table.

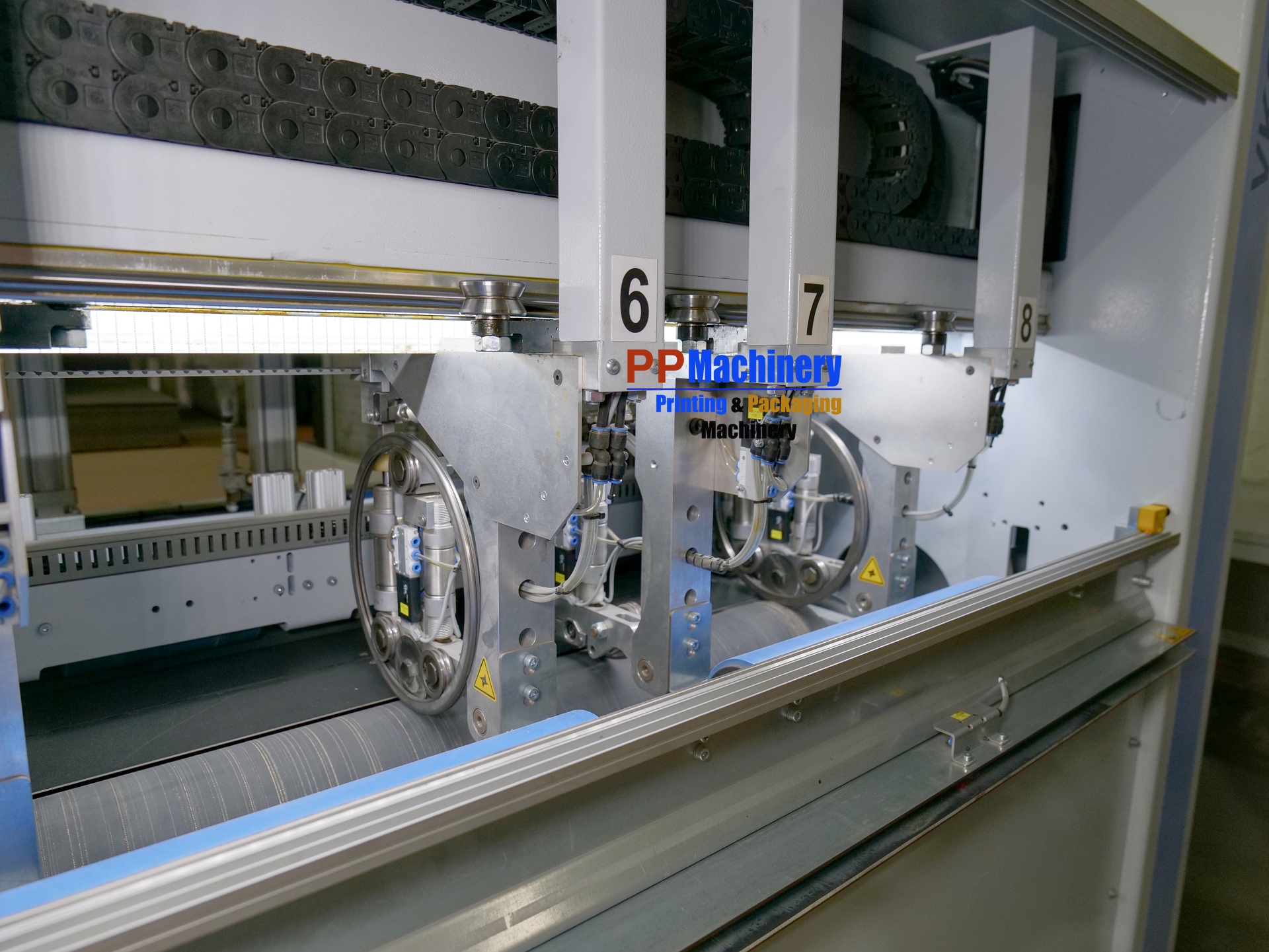

2nd cut

All thinkable, edgy cuts and fold patterns can be executed, even cuts for the creation of supporting grips. The machine can work in the back slicing drive and thus execute more longitudinal cuts and grooves than the longitudinal unit has in command (virtual longitudinal cutting unit).

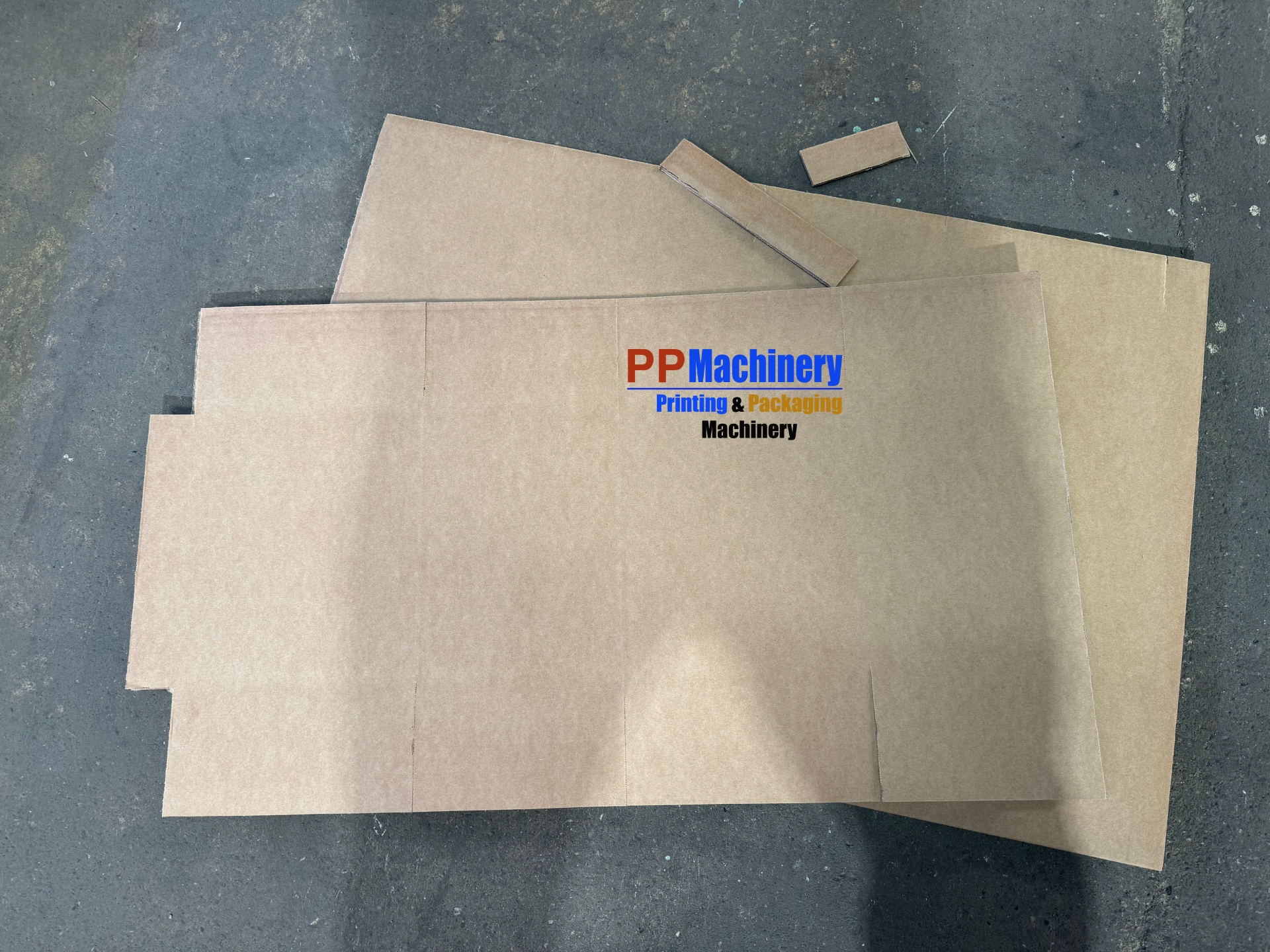

3rd Cutting pattern

• In the powerTouch control the “carton width”, “carton length” and “carton height” are entered which stand for the dimensions of the goods to be packaged. With these measures the machines produces a carton according to the selected pattern.

• Barcode scanner (optional equipment): carton pattern and measure of the packaging goods can be recalled through barcode sanning unit. This makes sense when the same workpieces are to be packaged in the same order over and over again.

• Also entire daily programs/ part lists of the packages to be produced can be created.